Our FabLab KPI was opened on June 19, 2018, as a result of the international ERASMUS+ FabLab project 561536-EPP-1-2015-1-UK-EPPKA2-CBHE-JP “Development of network infrastructure for youth innovation entrepreneurship support on FabLab platforms” (2015-2019). The project website is http://fablab-erasmus.eu/.

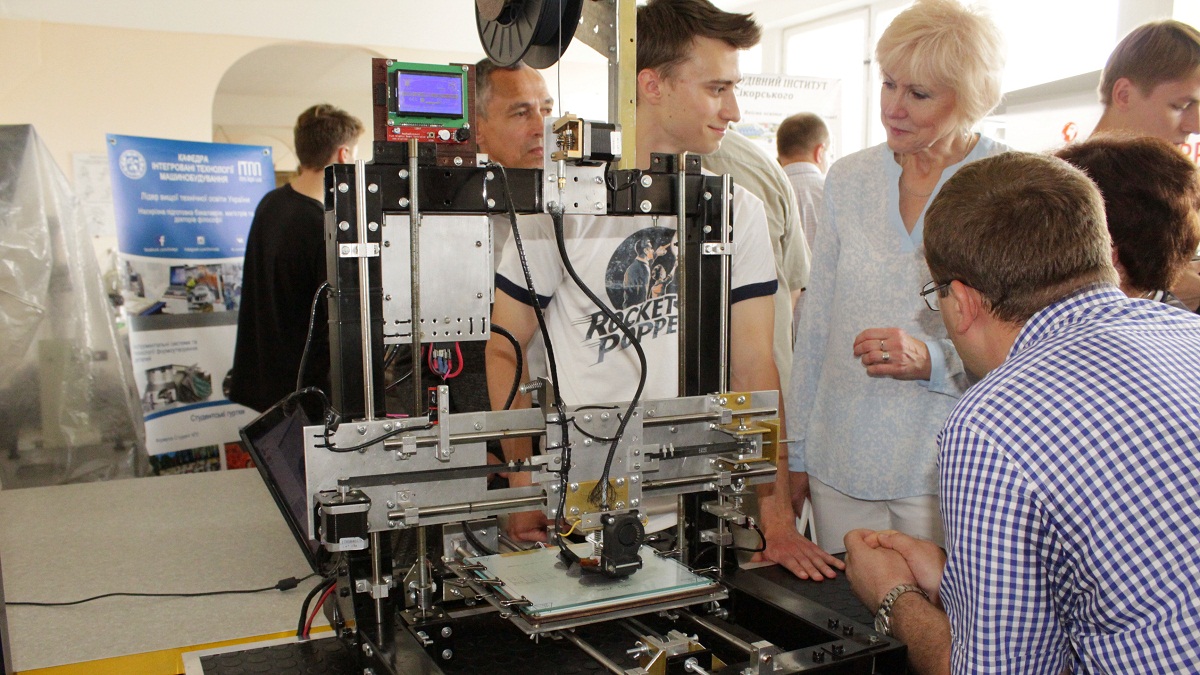

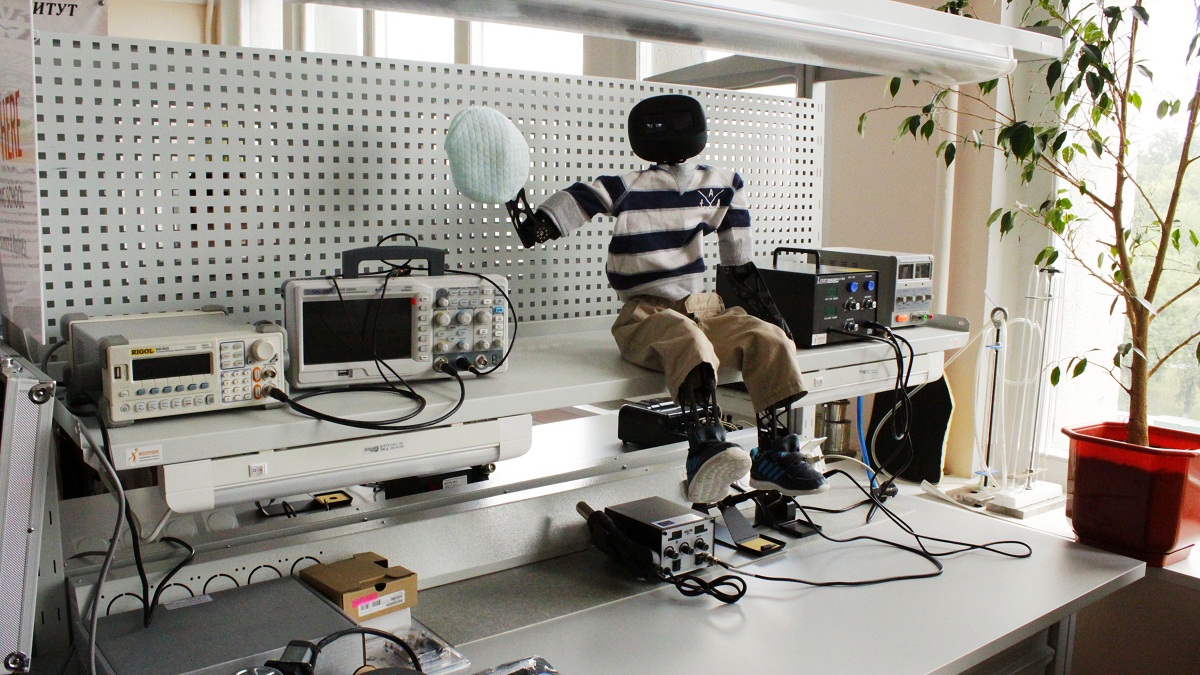

The major part of FabLab KPI equipment was purchased within this project. But we have also received additional equipment from our business partners and Igor Sikorsky Kyiv Polytechnic Institute. Now FabLab KPI has two premises in which all the equipment is located and where the FabLab KPI projects are being implemented. For machining work, we have two CNC milling machines, a drilling machine, workbenches for metalworking and other tools sets. Additive technologies are implemented using two 3D printers, and for electronics work, FablabKPI has two convenient workplaces equipped with power units, digital oscilloscopes, soldering stations, and other tool sets, etc. Taking into account that we are university-based FabLab, the major part of activities within FabLab KPI are performed by students of our university.

FabLab KPI operates on the basis of the Department of Integrated Manufacturing Engineering Technologies of the Mechanical Engineering Institute and the Department of Mathematical Methods of System Analysis of the Institute for Applied Systems Analysis and is part of the Sikorsky Challenge organization.

Projects

We have experience in implementing a number of educational and start-up like projects. Among educational projects, we are proud to name the Formula Student. Our startup projects are related to artificial intelligence, promising transport, wind power, robotics.

Activities

Our major activities are related to the automated design of products, programming of CNC machine tools and working on turning and drilling machines, models preparation and different objects and parts 3D printing, microcontrollers programming and software applications development. Additional activities include:

- Creation of scientific and technological innovations with the use of modern prototype manufacturing equipment (3D printing machines, laser cutting and CNC, Arduino electronic platforms, etc.);

- Teaching students and postgraduates the engineering basics of 3D modeling and automated designing, prototyping and 3D printing, the theory of solving inventive tasks, innovation marketing and project management;

- Stimulating the development of engineering creativity and improving the quality of students and postgraduates practical education;

- Training teachers in the field of 3D modeling and automated design, 3D printing and prototyping,

- Establishing interaction between university, business and production environments.

We invite you to take part in the FABLAB KPI activities, where you can try to implement your ideas, and then your project might be listed in the “Projects FABLAB KPI” gallery.